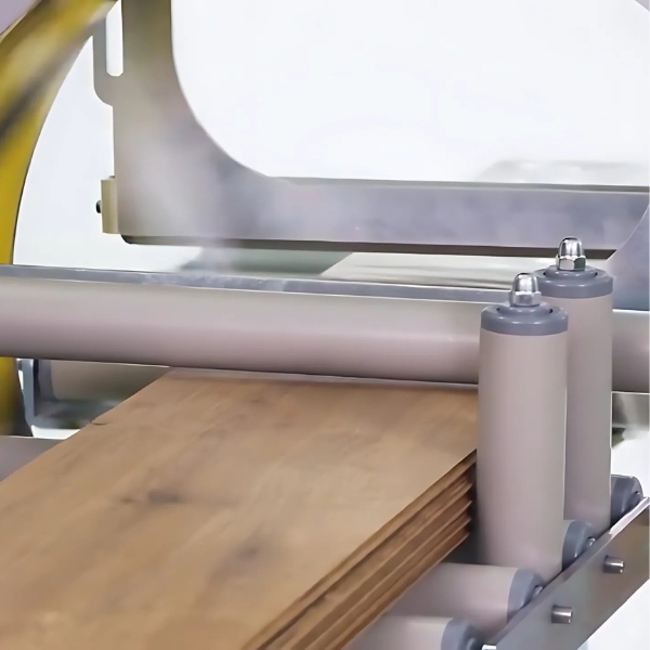

When to choose an orbital wrapper

An orbital pallet wrapper excels in securing long and irregularly shaped items like pipes, wooden planks, kitchen cabinets, timber flooring and general construction materials. Due to their length, these items can’t be secured by a traditional, turntable wrapping machine as these systems wrap items vertically.

Whether or not you should get an orbital wrapper largely depends on the shape and length of your packages. If you’re handling boxes and other rectangularly shaped packages, an automatic pallet wrapper is more suitable. But if you need to secure long and oddly shaped products, an orbital stretch wrapper will prove to be a great investment.